Smart Factory

MES/S&OP

- Respond promptly and flexibly

to sudden changes in the environment. - By linking highly accurate demand forecasting to production systems,

efficient production management is enabled.

Optimize production by producing only as much as is needed, when needed.

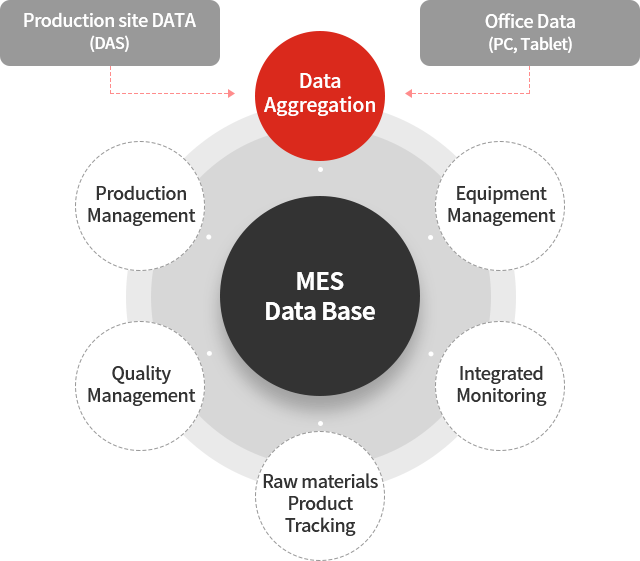

MES(Real-time production management system)

MES System

Reporting the latest data from production sites to managers,

and promptly adjusting production conditions according to circumstances in order to boost productivity

※ Domestic reseller for SIEMENS MES/MOM, R&D Suite

※ Domestic reseller for SIEMENS MES/MOM, R&D Suite

MES System 썸네일 상세설명

MES Data Base

- 데이터집계

- 생산현장 DATA(DAS)

- Office Data(PC, Tablet)

- 설비관리

- 통합모니터링

- 원료제품추적

- 품질관리

- 생산관리

-

- Ensuring visibility

- Real-time integrated monitoring throughout the manufacturing process

-

- Improved quality and productivity

- LOT management and traceability for raw materials and products to establish an unbroken chain of management from quality inspection to results, analysis and improvement

-

- Equipment monitoring and response

- Status monitoring, equipment maintenance and problem prevention

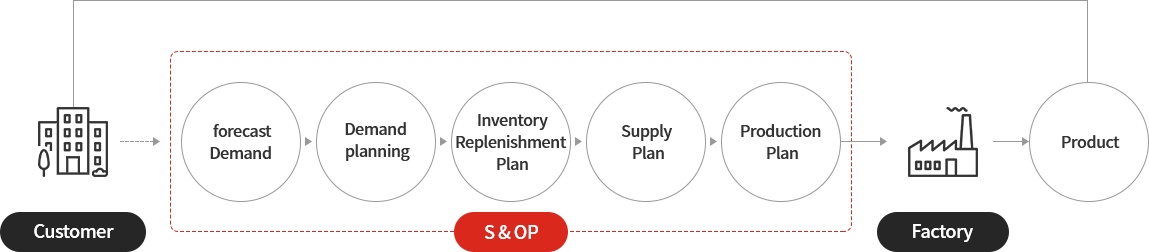

S&OP (Sales and operations planning system)

S&OP(SCP) System

Customer needs-based demand forecasting and production optimization

to reduce inventory and enhance profitability

S&OP(SCP) System 썸네일 상세설명

- 고객

- 수요예측

- 수요계획

- 재고 보충계획

- 공급계획

- 생산계획

- 공장

- 제품

-

- 1Demand forecast

- Statistics and AI

based baseline forecasts

-

- 2Demand planning

- Sales information (promotions, etc.)

reflected in demand planning

-

- 3Inventory replenishment plan

- Assessment of appropriate inventory levels by item/grade

Replenishment volumes given in consideration of available stock

and expected incoming warehousing volume

-

- 4Supply Plan

- Production plans

and long-term materials plans

for combined company-wide factory capacity

-

- 5Short-term production plan

- Production plans by date, factory and line

Re-planning

when needed in response to urgent orders

-

- Demand forecasting

- Statistics and machine learning-based demand forecasting system

-

- Centralized inventory control system

- Inventory replenishment plans established based on systematic item grades

-

- Production plan optimization system

- Establishing production plans reflecting inventory levels and production data

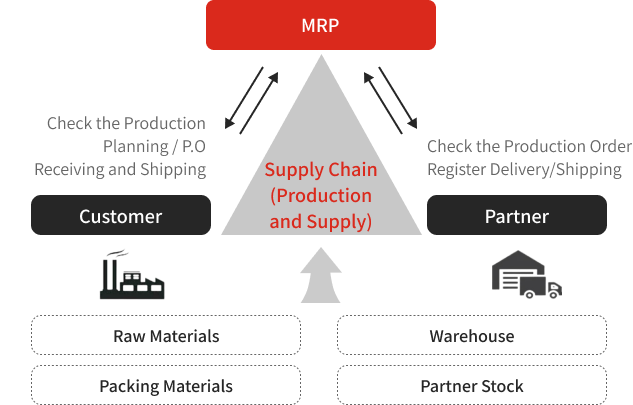

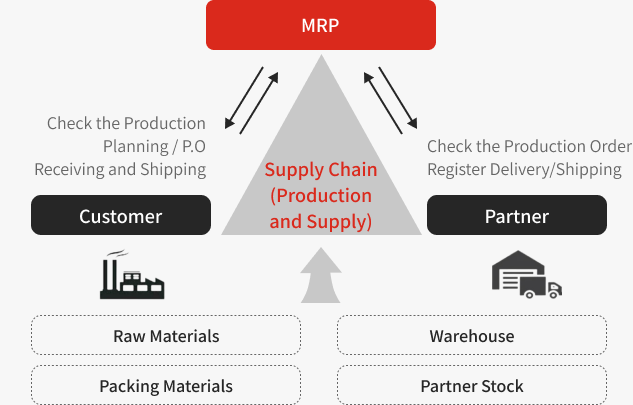

MRP System

MRP System

Reduce the stock and improve profitability by identifying materials needed

to produce and estimating delivery schedule based on the customer needs

MRP

Check the Production Planning / P.O Receiving and Shipping

Check the Production Order Register Delivery/Shipping

Customer

Supply Chain (Production and Supply)

Partner

- Raw Materials

- Packing Materials

- Warehouse

- Partner Stock

-

- Standardization of System Work

- Computerization of handwriting and Automation of repetitive work

-

- Simplification of PO Work

- PO Automation and Build the Supplier communication channel

-

- Reduction of Unused Stock

- Improve profitability by reducing overordering / misordering

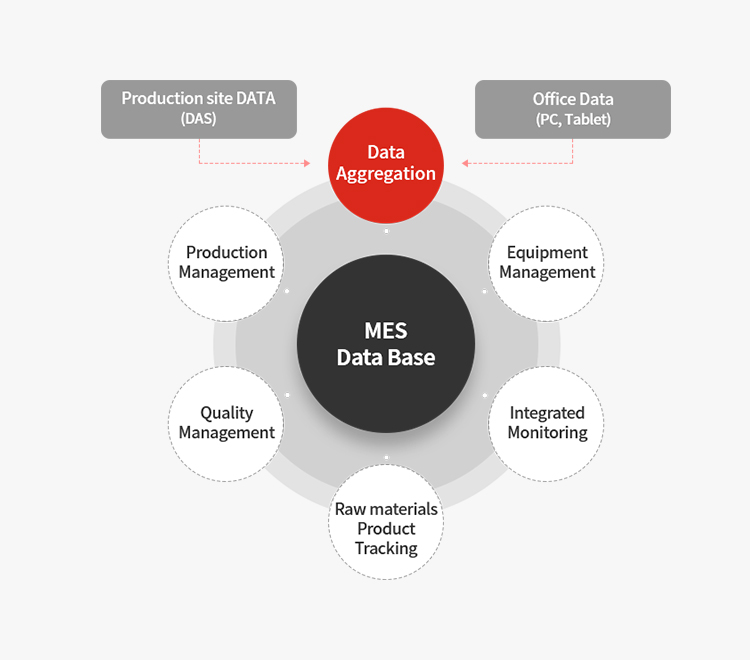

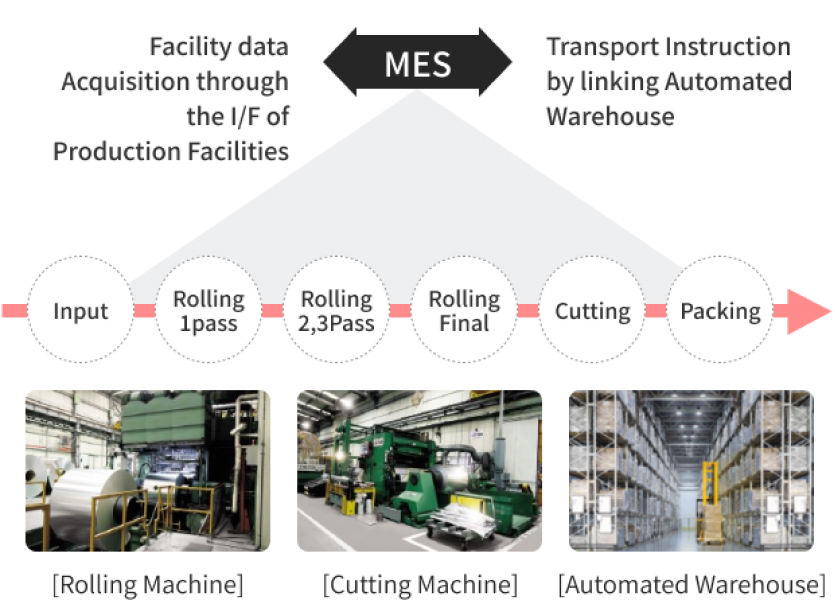

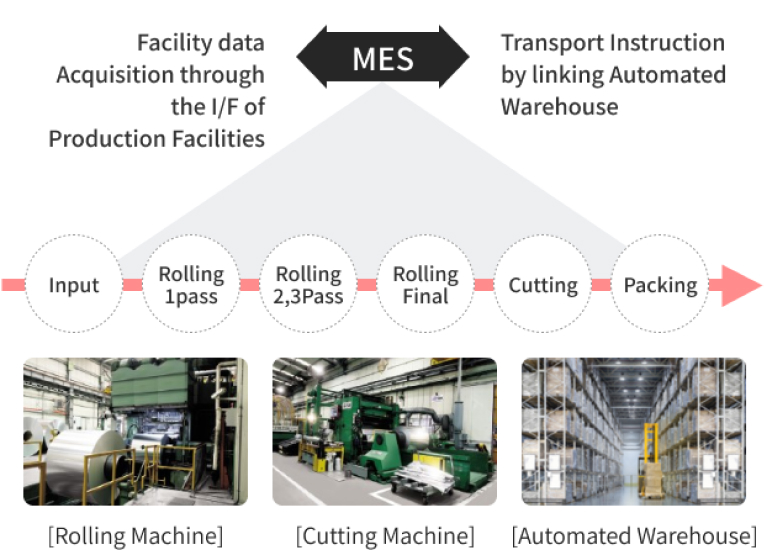

MES (Real-time production management system)

MES System

Reporting the latest data from production sites to managers,

and promptly adjusting production conditions according to circumstances in order to boost productivity

MES System 썸네일 상세설명

MES Data Base

- 데이터집계

- 생산현장 DATA(DAS)

- Office Data(PC, Tablet)

- 설비관리

- 통합모니터링

- 원료제품추적

- 품질관리

- 생산관리

-

- Ensuring visibility

- Real-time integrated monitoring throughout the manufacturing process

-

- Improved quality and productivity

- LOT management and traceability for raw materials and products

to establish an unbroken chain of management

from quality inspection to results, analysis and improvement

-

- Equipment monitoring and response

- Status monitoring, equipment maintenance and problem prevention

S&OP (Sales and operations planning system)

S&OP(SCP) System

Customer needs-based demand forecasting and production optimization

to reduce inventory and enhance profitability

S&OP(SCP) System 썸네일 상세설명

- 고객

- 수요예측

- 수요계획

- 재고 보충계획

- 공급계획

- 생산계획

- 공장

- 제품

-

- Demand forecasting

- Statistics and machine learning-based demand forecasting system

-

- Centralized inventory control system

- Inventory replenishment plans established based on systematic item grades

-

- Production plan optimization system

- Establishing production plans reflecting inventory levels and production data

MRP System

MRP System

Reduce the stock and improve profitability by identifying materials needed to produce and estimating delivery schedule based on the customer needs

MRP

Check the Production Planning / P.O Receiving and Shipping

Check the Production Order Register Delivery/Shipping

Customer

Supply Chain (Production and Supply)

Partner

- Raw Materials

- Packing Materials

- Warehouse

- Partner Stock

-

- Standardization of System Work

- Computerization of handwriting and Automation of repetitive work

-

- Simplification of PO Work

- PO Automation and Build the Supplier communication channel

-

- Reduction of Unused Stock

- Improve profitability by reducing overordering / misordering

Meet the real references.

Meet the real references.

A Company(’21.3~’22.05)

- [Production Management]

-

- · Minimize hand-writing by collecting facility date

- · Process Management through the Material automation transport system

- [Quality Management]

-

- · System Management based on Quality Test, Alarm during spec breakaway

- · Secure ability of quality management by gathering process quality data

- [Facility Management]

-

- · Build the data based facility system to improve facility overall efficiency

- · Support the maintenance plan by facility status

- Any questions?

-

Please don’t hesitate to post your questions.

We’ll do our best to reply as soon as possible.